From snail pace to cheetah chase, experience the power of line balancing.

Imagine turning your production line from a sluggish snail to a sleek cheetah, churning out products faster and more efficiently. Sounds like a dream, right?

Well, it’s not magic, its line balancing, and this is the secret weapon of successful businesses.

Importance of Line Balancing:

In today’s competitive world, every second counts. Line balancing optimizes your production flow, eliminating those frustrating bottlenecks that drain your profits.

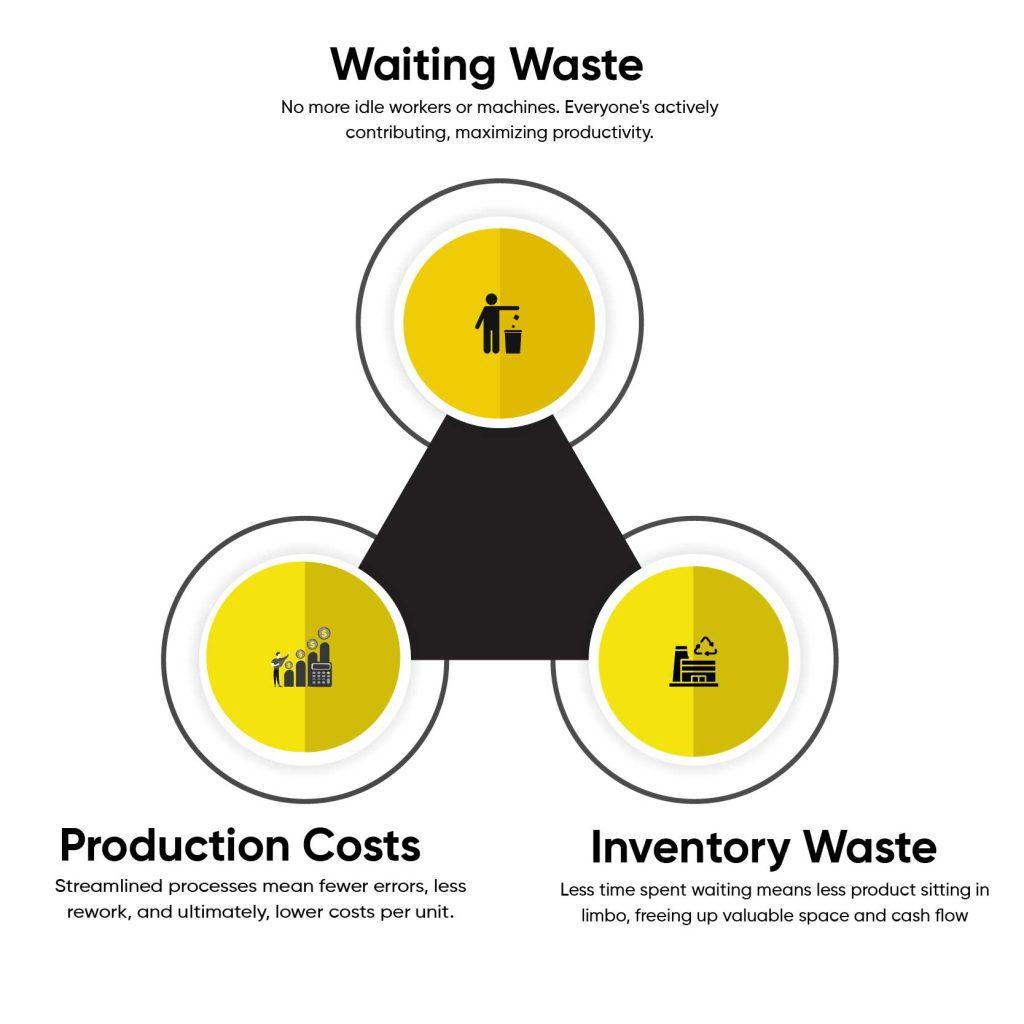

It’s like having a well-oiled machine where tasks seamlessly flow from one station to the next, reducing:

Waiting waste: No more idle workers or machines. Everyone’s actively contributing, maximizing productivity.

Inventory waste: Less time spent waiting means less product sitting in limbo, freeing up valuable space and cash flow.

Production costs: Streamlined processes mean fewer errors, less rework, and ultimately, lower costs per unit.

Think of it as building a dam against inefficiency. Line balancing absorbs those internal hiccups (machine breakdowns, material delays) and external fluctuations (changing demand, supplier issues) without derailing your entire production line.

The Problem:

But achieving that perfect balance is no walk in the park. Line balancing can be a tricky puzzle. Tasks have varying times, workers have different skillsets, and machines have their own limitations.

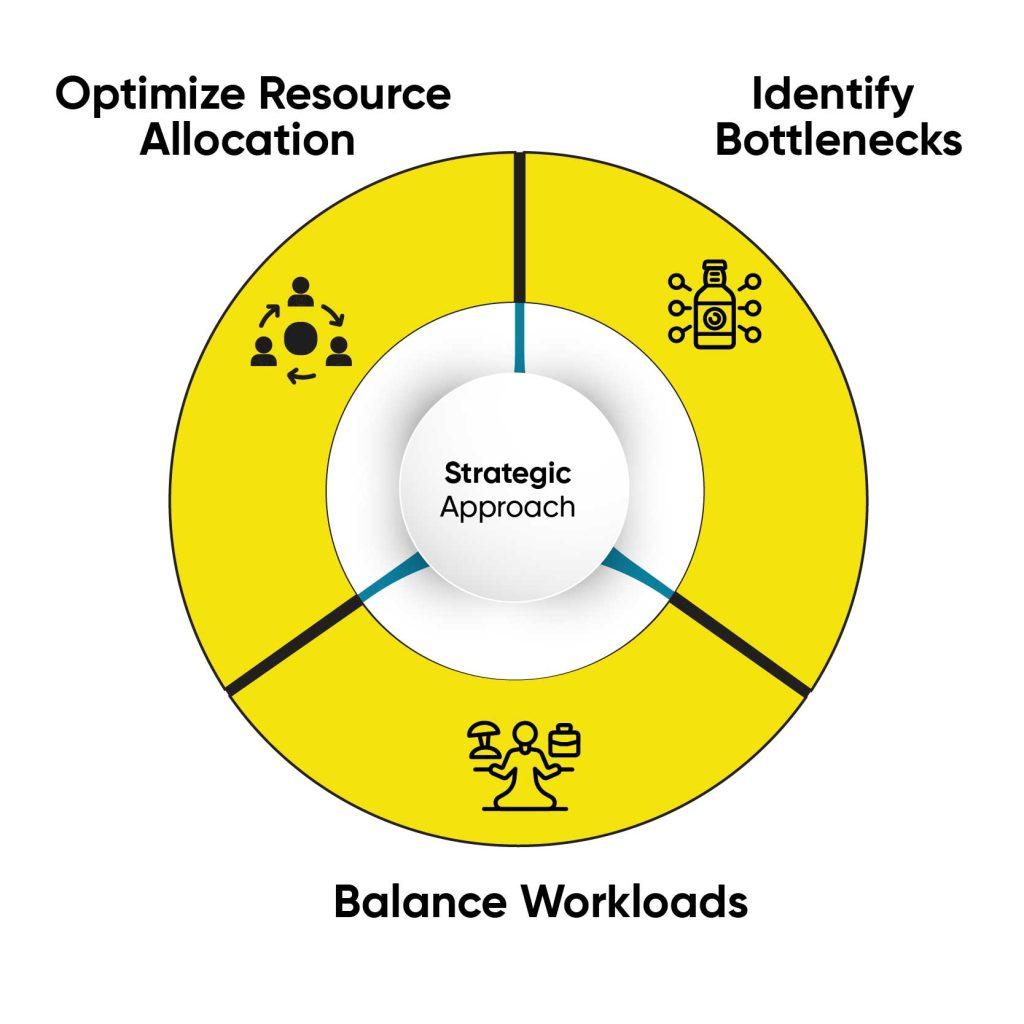

Throwing it all together like a messy salad won’t work. You need a strategic approach to:

Identify bottlenecks: Where’s the clog in your system? Pinpoint the tasks taki

Balance workloads: Ensure each station has roughly the same amount of work, preventing idle hands and overloaded

Optimize resource allocation:

Solutions

Fear not, there’s a toolbox full of line balancing techniques for every organisation

The stopwatch method: Time each task, then shuffle and assign them to station

Heuristics: Use formulas and algorithms to find the optimal assignment of tasks to stations, like the

Software tools: Invest in user-friendly line balancing software that takes the guesswork out of the process.

Remember, line balancing is all about finding the sweet spot between time, manpower, and machine capacity. It’s not about working faster, but working smarter.

Applications:

The beauty of line balancing is its versatility. Whether you’re a bakery churning out loaves or a tech start-up assembling gadgets, this powerful tool can be applied across industries:

Manufacturing: Assembly lines, packaging, and production processes.

Food and beverage: Processing lines, bottling, and packaging.

Service industries: Call centres, customer service queues, and even healthcare

workflows.

Line balancing is more than just a trendy term, it’s a revolutionary strategy for SMEs, start-ups, and business executives. It’s the secret key to uncovering latent productivity, enhancing profits, and staying ahead in the race.

So, don’t let your production line crawl at a snail’s pace, equip it with the tools of line balancing and morph it into a swift cheetah, primed to dominate the market!