The Indian elevator industry is a booming business, expected to reach a whopping ₹73,827 Crore by 2031!

Imagine if you run a factory that builds elevators and its spare parts, those incredible machines that whisk you up and down tall buildings. But your factory floor is like a game of Tetris gone wrong.

Parts are scattered everywhere; orders get lost in the shuffle and precious time ticks by while your team hunts for what they need. This was the reality for Maruti Elevators, a Surat-based elevator parts manufacturer with big dreams of conquering the Indian market.

Maruti Elevators, with their 15 years of experience, had the talent and the product, but their old-school way of working was holding them back.

Stratefix Consulting, a team of business growth experts, stepped in to help them transform their factory floor from a cluttered mess into a smooth-running, profit-making machine.

Often the road to change was filled with skepticism and many struggles with outdated operational practices.

At Maruti Elevators, we saw the business owners working 12-14 hours a day involved in each activity, relying on pocket diaries and WhatsApp for order management, leading to cluttered mess and inefficiency. They did see the gaps but had no idea how to fix them.

Here’s how our consultants turned this traditional business into a model of modern efficiency, doubling their sales and reducing operational delays.

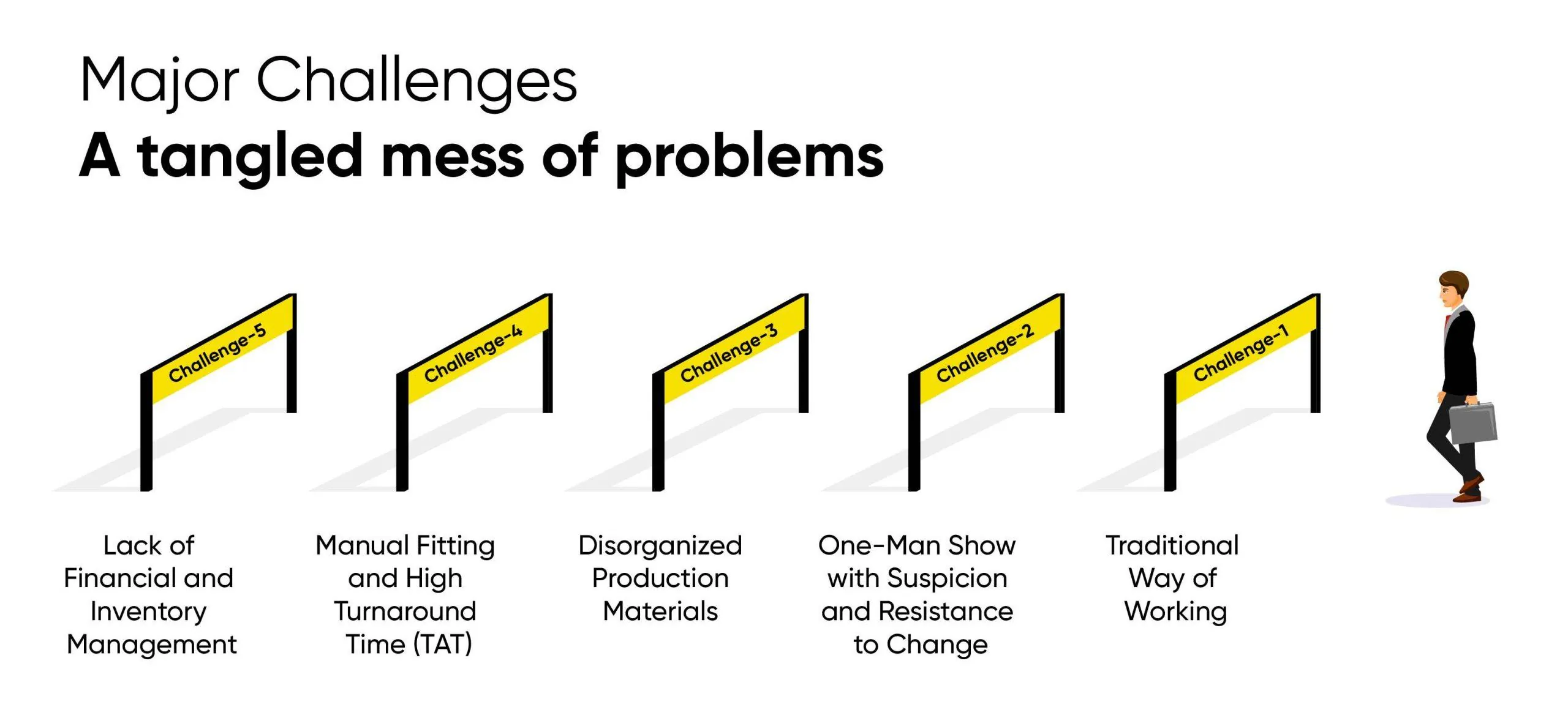

1. Traditional Way of Working

The business was run in a highly traditional manner with no tracking systems in place. Pocket diaries were used for taking sales orders in handwritten notes, often leading to lost information, confusion and disorganization.

This unprofessional approach made it difficult to track progress and ensure customer satisfaction.

2. One-Man Show with Suspicion and Resistance to Change

All the decision-making power rested with one person, creating a single point of failure and hindering growth. Initially, the management was suspicious of Stratefix’s activities, questioning the need for change and the proposed solutions.

3. Disorganized Production Materials

Materials, spare parts, and products were unorganized, leading to inefficiency and wasted time. There was no systematic plan for production, leading to bottlenecks and delays. Imagine trying to build an elevator without a blueprint – that’s what Maruti Elevators was facing!

4. Manual Fitting and High Turnaround Time (TAT)

Parts were piled everywhere, with no clear system for organizing or tracking them. They were fitted manually after production, requiring significant time and effort to move between one floor department to another.

The order to dispatch time was between 12-24 hours.

5. Lack of Financial and Inventory Management

There was no process for credit management or collection. Inventory tracking was poor, and forecasting was non-existent. No one knew what they had, where it was located, or how much of it they needed. This led to delays, frustrated customers, and wasted resources.

This wasted precious space and made it difficult to find what they needed, leading to delays and frustrated workers.

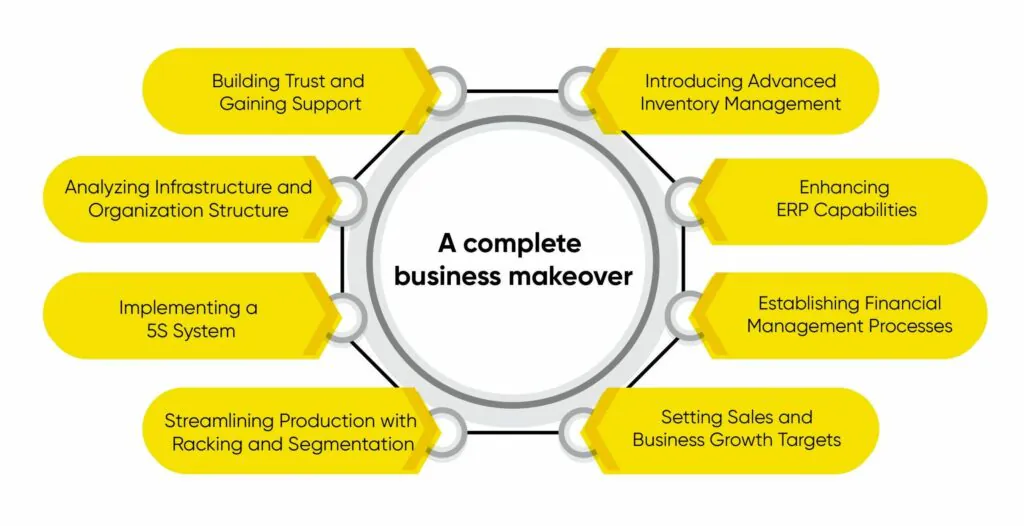

Stratefix Consulting didn't just throw a band-aid on the problems; our team performed a complete business makeover.

- Building Trust and Gaining Support

Stratefix ensured that the owners were informed about every step. On site Operation consultants explained the “what, why, where, how & when” of each activity to build trust and support for the changes.

We always ensure transparency by explaining each step before implementation, detailing what is being done, why it is necessary, and how it will positively impact the organization

- Analyzing Infrastructure and Organization Structure

Stratefix conducted a thorough analysis of the business’s infrastructure and organizational structure, providing a roadmap for the rest of the process.

- Implementing a 5S System

To improve efficiency, Stratefix introduced the 5S system (Sort, Set in order, Shine, Standardize, Sustain). This powerful Japanese organizing method brought order to the chaos. This system was applied to materials, spare parts, and production processes.

Impact:

- The overall TAT for production to finished goods improved significantly.

- Organized materials reduced unwanted clutter, enhanced efficiency and made it easy to find parts.

- Streamlining Production with Racking and Segmentation

A racking process and segmentation in carets were introduced, making the production process faster and more organized.

We implemented a system for tracking inventory, managing orders, and planning production. It was like giving Maruti Elevators a digital brain to keep everything organized and running smoothly.

Impact:

- Order to dispatch time reduced from 12-24 hours to just 1-2 hour.

- Introducing Advanced Inventory Management

Stratefix introduced advanced stock and inventory management, moving beyond the vital four (Raw Materials, WIP, Maintenance Items, Finished Goods) to include:

- Maintenance, Repair, and Operations (MRO) Goods

- Packing and Packaging Materials

- Safety Stock and Anticipation Stock

- Decoupling Inventory

- Cycle Inventory

- Service Inventory

- Transit Inventory

- Theoretical Inventory

- Excess Inventory

Impact:

- Potential savings of 30-40% in cost and space.

- Improved tracking and reduced inventory wastage.

- Enhancing ERP Capabilities

Stratefix revamped the Tally software, aligning it with the company’s unique requirements and ensuring compatibility.

Impact:

- On-time data generation improved production understanding.

- Employees started using the ERP system effectively, leading to better data management.

- Every minute saved is a rupee earned!

- Establishing Financial Management Processes

Stratefix implemented processes for credit management, collections, and sales documentation.

Impact:

- Clear visibility of quoted prices and streamlined billing processes.

- Reduction in errors and delays in financial transactions.

- Setting Sales and Business Growth Targets

Monthly, quarterly, and yearly sales targets were defined. A new sales team was established, and training focused on their core industry sector.

Impact:

- Expansion into new territories, including Maharashtra, with fully trained sales teams.

- Successful dealers meet with 100+ attendees to kick-start sales in the new market.

- The new market contributed 25% of overall sales.

Detailed Results achieved

- Streamlined Supply Chain Management

- Implemented organized racking systems and segmentation in carets.

- Resulted in faster order processing and reduced turnaround times.

- Improved Collaboration and Communication

- Regular meetings and clear communication channels established.

- Management and employees aligned on goals and processes.

- Accurate Financial Reporting

- Advanced ERP and inventory systems improved financial data accuracy.

- Enabled timely and precise financial reporting.

- Reduced Machine Downtime

- Improved inventory management reduced waiting times for materials.

- Machines utilized more efficiently, decreasing downtime.

- Optimized Production Leading to Increased Sales

- Efficient processes led to faster production cycles.

- Sales doubled as a result of improved operational efficiency.

- Improved Customer Satisfaction

- Reliable and faster order fulfillment increased customer trust.

- Higher customer satisfaction resulted in repeat business.

- Automated Invoicing and Payment Management

- Financial processes streamlined with new systems.

- Automated invoicing reduced errors and expedited payments

- Enhanced Vendor Management and Simplified Purchasing

- Clear vendor agreements and regular meetings improved vendor relations.

- Simplified purchasing processes reduced delays.

- Quality and Inventory Management

- Advanced inventory tracking ensured consistent quality control.

- Organized inventory reduced wastage and optimized space utilization.

The result was a highly efficient operation, ready to scale new heights in the competitive industry.

Maruti Elevator’s owner, Mr. Shah, Says it best “Stratefix Consulting helped us transform our business. We’re now a well-organized, efficient company with a bright future.“

“Don’t be afraid to break the status quo. Sometimes, the biggest growth comes from making bold changes.”

Don’t be afraid to step outside your comfort zone and implement new systems and processes. Change can be scary, but it can also lead to amazing growth. That’s exactly what Mr.Shah did with Stratefix Consulting by his side.

Remember, these are just some of the many benefits Maruti Elevators experienced. Stratefix Consulting’s approach is like a Swiss Army Knife for businesses – adaptable, effective, and designed to tackle any challenge.

Here are some additional points to remember:

- We go beyond strategy. We don't just create a plan; we implement it with a hands-on approach, ensuring your success.

- The power of a good consultant: A consultant like Stratefix can be a game-changer for your business. They bring expertise, fresh perspectives, and a proven track record of success.

- We understand the Indian market. We have a deep understanding of the unique challenges faced by Indian MSME businesses.

- Focus on your people:Your employees are your greatest asset. Empower them, train them, and create a work environment where they can thrive.

- We have a proven track record.With over 450 satisfied clients and a team of 85+ experts, we have the experience and expertise to get you results.

Don’t let your business become stuck on the ground floor.

Contact Stratefix Consulting today and schedule your free consultation!