In the fast-evolving landscape of manufacturing and warehousing, traditional working methods often lead to inefficiencies that can cost businesses both time and money.

Lifestyle furniture, a leading manufacturer in the furniture industry, faced significant operational challenges due to its unorganized workspace, outdated processes, and lack of digital tools.

They relied heavily on manual systems for order tracking, inventory management, and stock control, which created bottlenecks and hindered the Lifestyle furniture and Xylus’s ability to grow and compete in a rapidly modernizing industry.

Despite having sufficient space and resources, their operations were marred by inefficiency, lack of organization, and outdated working methods.

Mukesh Bangar, founder of Lifestyle furniture, sought help from Stratefix Consulting to resolve these operational inefficiencies and implement a modern, streamlined workflow that would allow it to scale.

Through a comprehensive approach that included process reorganization, inventory management, and the introduction of new technology, Stratefix helped transform this traditional company into a more efficient and scalable business.

The Challenges

When Stratefix Consulting first engaged with the client, the company was struggling with several key issues. The following challenges were identified:

- Unorganized Workspace and Inventory: The company had a large space, but it was underutilized due to lack of organization. Materials were stored haphazardly, often on the floor, making it difficult to find the necessary supplies in a timely manner. This disorganization slowed down the production process and increased the likelihood of errors.

- Traditional, Manual Processes: Orders were recorded manually in register books, with no systematic approach to tracking inward and outward material movement. This old-fashioned method created delays and confusion, especially when the team had to manually coordinate orders, leading to missed opportunities.

- Absence of Real-Time Stock Tracking: There was no system in place to track the stock of raw materials or finished products. The team had to physically inspect the stock or coordinate via phone calls to check material availability, often losing valuable time and risking delays in order fulfilment.

- Lack of Digitalization and Modern Tools: The business was operating without a digital system for managing inventory or tracking orders. This lack of technology made it difficult to keep accurate records, optimize stock levels, or improve overall efficiency.

- Inefficiency in Stock Management: With two large godowns (warehouses) used for production and dispatching, the team at Lifestyle furniture struggled to manage stock effectively. Approximately 10-15% of their stock was either replaceable or needed to be discarded, leading to wastage and increased operational costs.

These challenges hampered the company’s ability to scale, delayed production times, and increased operational inefficiencies. To overcome these roadblocks, the business needed a complete overhaul of its operations.

The Indian Furniture Manufacturing Industry Overview

India’s furniture market is witnessing rapid growth, driven by increasing urbanization, rising disposable incomes, and the expanding e-commerce industry. According to a report by TechSci Research, the Indian furniture market is expected to grow at a compound annual growth rate (CAGR) of around 12.91% during the period of 2021-2026.

Despite this growth, the industry remains fragmented, with over 80% of the market consisting of unorganized players, similar to the client in this case.

This reliance on traditional methods, limited technological adoption, and inefficient processes hinders many manufacturers from achieving full potential in terms of profitability and scalability.

As the industry moves toward modernization with an increased focus on efficient supply chains, automation, and technology, companies that fail to adapt risk being left behind.

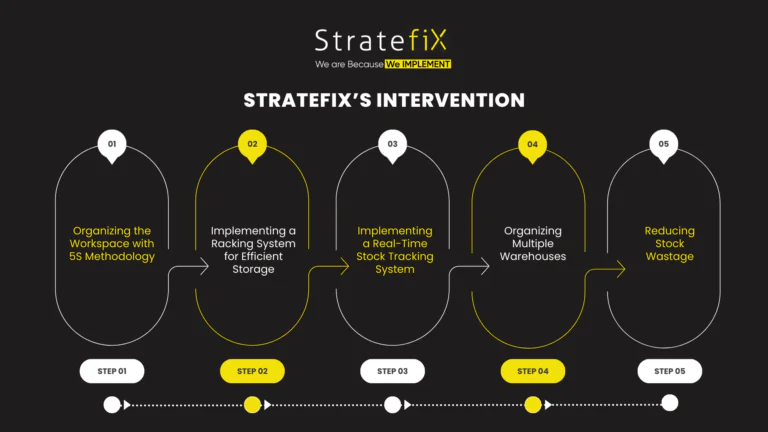

Stratefix’s Intervention

Stratefix Consulting brought a structured approach to resolving the client’s issues, starting with organizing the workspace and ending with the implementation of digital tools. By implementing modernized processes and tools, we made sure Lifestyle Furniture is better positioned themselves to compete in this booming market.

The goal was to streamline operations, reduce wastage, and improve the overall efficiency of the company’s processes.

Step 1: Organizing the Workspace with 5S Methodology

The first step in the transformation process was to organize the physical workspace using the 5S methodology—a lean manufacturing principle designed to optimize efficiency by organizing the workspace in a way that promotes order and cleanliness.

- Sorting (Seiri): The company had a large amount of clutter and unorganized materials scattered around the warehouse.

- Stratefix worked with the team to sort through all materials, identifying what was necessary and discarding what was not.

- This process immediately freed up space and reduced the time spent looking for supplies.

- Set in Order (Seiton): After clearing out the unnecessary materials, Stratefix helped the client introduce a more organized system for storing materials. However, without a proper racking system, the space was still underutilized.

Step 2: Implementing a Racking System for Efficient Storage

- To address the issue of disorganized materials being stored on the floor, Stratefix recommended the installation of a racking system.

- Once implemented, this system allowed the team to organize materials by type, size, and usage, making it easier to locate items and reducing the time wasted on searching for supplies.

The introduction of racks optimized space utilization and made inventory management far more efficient.

Step 3: Implementing a Real-Time Stock Tracking System

One of the most significant changes was the introduction of a digital stock tracking system. Before Stratefix’s intervention, Lifestyle furniture had no reliable way to track inventory levels in real time, which resulted in delays and inefficiencies.

Key benefits of the new system included:

- Real-time Inventory Updates: The new system provided up-to-the-minute reports on stock levels, helping the team track inward and outward movement of materials in real time.

- Centralized Data Management: The company now had a single digital platform where all inventory data was recorded, reducing errors and miscommunication that stemmed from their earlier manual processes.

- Efficient Order Fulfilment: With livestock updates, the team could immediately check the availability of materials required to fulfil orders, reducing delays and improving customer satisfaction.

By installing a robust software system that allowed for live tracking of stock—both raw materials and finished goods—the company was able to streamline the entire inventory process.

Step 4: Organizing Multiple Warehouses

The client operated two godowns, one dedicated to production and the other for dispatching finished products. Managing inventory across these two locations was challenging without a proper system in place.

Stratefix implemented a centralized inventory management system that enabled the company to track stock levels at both locations simultaneously.

- Godown 1 (Production): All raw materials were tracked as they moved into production, providing real-time visibility into material usage and stock levels.

- Godown 2 (Dispatch): Once products were finished, they were moved to the dispatch godown, where they could be tracked until shipped to the customer.

This system ensured better coordination between the production and dispatch teams, improving overall workflow and reducing lead times for order fulfilment.

Step 5: Reducing Stock Wastage

- One of the critical issues the company faced was that approximately 10-15% of its stock was either replaceable or needed to be discarded.

- This wastage occurred because the company often ordered materials in bulk without properly assessing stock levels or demand.

- With the new inventory tracking system in place, Stratefix helped the company optimize its procurement process, ensuring that only the necessary amount of material was ordered based on current stock levels and forecasted demand.

This reduced wastage significantly and allowed the company to operate more cost-effectively.

Results Achieved

The transformation led by Stratefix Consulting delivered significant improvements across the board, helping the company move away from inefficient traditional methods and adopt a modern, scalable approach. The key results achieved include:

- Enhanced Workspace Efficiency: By organizing the workspace and implementing a racking system, the company was able to fully utilize its existing space, improving overall efficiency and reducing clutter.

- Faster Order Fulfilment: The real-time stock tracking system significantly reduced the time required to check inventory levels and coordinate between teams. This allowed the company to fulfil orders more quickly and respond to customer needs in a timely manner.

- Reduced Wastage: The introduction of a digital stock tracking system and optimized procurement process reduced the amount of wasted stock from 10-15% to below 4%. This helped the company cut costs and operate more sustainably.

- Improved Coordination Across Warehouses: The centralized inventory management system improved communication and coordination between the production and dispatch godowns, resulting in a smoother workflow and faster shipping times.

- Increased Scalability: With the new systems in place, the Lifestyle furniture is now better equipped to scale its operations. The digital tools and organized processes provide the foundation needed to expand into new markets or increase production without encountering the same bottlenecks that hindered growth in the past.

Industry Trends and Future Outlook

The Indian furniture industry is set to continue its upward trajectory, driven by rising consumer demand for customized and affordable furniture solutions.

In this context, companies that adopt modernized, efficient operations will be best positioned to capitalize on the market’s growth.

Moreover, digitalization and automation are becoming essential for survival in the manufacturing industry, particularly in a market where consumers expect faster delivery times and more personalized products.

With the help of Stratefix Consulting’s operation management experts, the client is now well-positioned to lead in this evolving landscape, having implemented the necessary systems and tools to compete effectively.

Conclusion

Stratefix’s operational excellence consulting played a crucial role in transforming the client’s business from an unorganized, traditional operation into a streamlined, efficient, and modernized Lifestyle Furniture.

By implementing a mix of physical reorganization, digital tools, and strategic process changes, the client was able to achieve significant operational improvements, reduce wastage, and position itself for future growth.

This case study serves as a testament to how MSMEs, SMEs and even well-established companies can benefit from lean manufacturing consultants, and how adopting the right strategies can lead to sustainable growth in an increasingly competitive market.

Contact us today to find out how we can help you achieve excellence.